May 29, 2025

May 27, 2025

Apr 14, 2025

Apr 07, 2025

B4, Qingdao High-Tech Zone, No. 17 Songyuan Road, Qingdao.

+86 13864822549

How are Haosail's sheet metal products made?

In these decades, the domestic sheet metal processing industry has also witnessed rapid development along with the gradual rise of domestic machinery manufacturing industry, communications and electronics industry, automobile and shipbuilding, aerospace and other industries.

Compared with other machined products, sheet metal products pay more attention to the appearance quality and require higher surface treatment.

In this regard, the Haosail technical department has detailed and clear requirements from material selection to surface treatment.

1. Plates of standard thickness

The cold rolled sheets we selected are all in line with the Chinese, British and international standards, and can ensure adequate strength under the same specifications.

2. Meticulous pre-processing

In order to make the paint more firm, we take longer time to do the acid pickling and phosphating treatment of sheet metal parts.

Process flow of sheet metal pretreatment: pickling-degreasing-washing-surface regulation-phosphating-washing

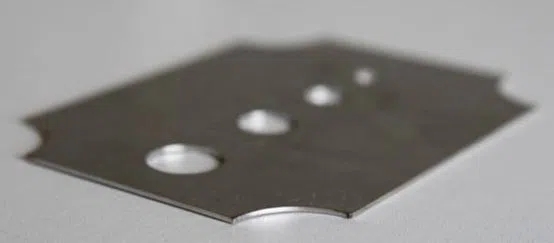

3. Imported precision cutting equipment

For parts with high precision dimension requirements, we use imported equipment to complete them.

4. Better welding equipment

We use special fixtures and better welding equipment to ensure the reliability of welding.

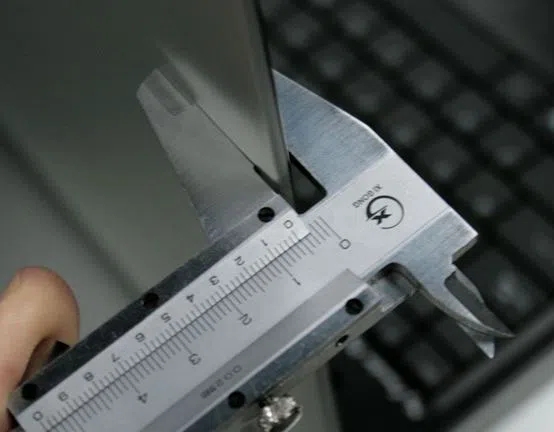

5. Don't allow any deviation

Each component is measured to ensure the accuracy of key dimensions and bring better product experience.

6. Imported spraying equipment

High-end equipment means higher production costs, but it is the real quality assurance.

We insist on using the best equipment to ensure the quality and performance of our products.

We insist on continuous improvement of product design to provide you with better product experience.